|

| A scarf |

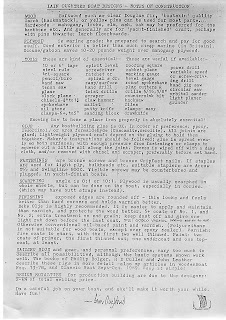

By the way, I found this picture on a website dedicated to Dr Who scarfs, actually no, a website dedicated to Dr Who scarfs as worn by Tom Baker. (The longest serving of all the Dr's.) If you don't believe me, look at this.

Dr Who Scarfs

Anyway, I have now discovered that if you spell it scarph, it is a type of joint. Yes yes, two months ago, I thought a joints was, well, you know.

Anyway, there are multitude ways to join two bits of wood together, and one of them is a scarph joint. With some trepidation we decided it was time to break out the planks and have a crack at gluing a couple of them together. The resulting two hour table building episode can be found in a previous blog.

So, we read the instructions and set to with my second hand plane. I can tell you that this was a nervy moment. We were chipping away at bits of wood that would eventually become the boat. An error here could mean a rather annoying leak, especially as we were working on the garboard plank, the one that is deepest in the water. It was surprisingly painless, we probably took too long over it, and were terrified of using time saving electric appliances on our rather expensive bits of plywood.

The pictures below show the results. The first shows two planks on top of each other, planed of course. the fact that the laminates aren't 100% parallel indicates we haven't got it 100% right. In the other, Chris is applying a coat of clear epoxy to the joints prior to mixing in the "white stuff" that thickens it up and makes it glue.

| ||

| Two bits of wood, planed. That's my reconditioned plane by the way |

|

| Wetting the joint with epoxy prior to the gluing |

The results were a very nicely glued joint, not perfect. but pretty good for a first attempt.

The boat I had in mind for this trip was a

The boat I had in mind for this trip was a